한 걸음 두 걸음

EDM Boat Sampling 본문

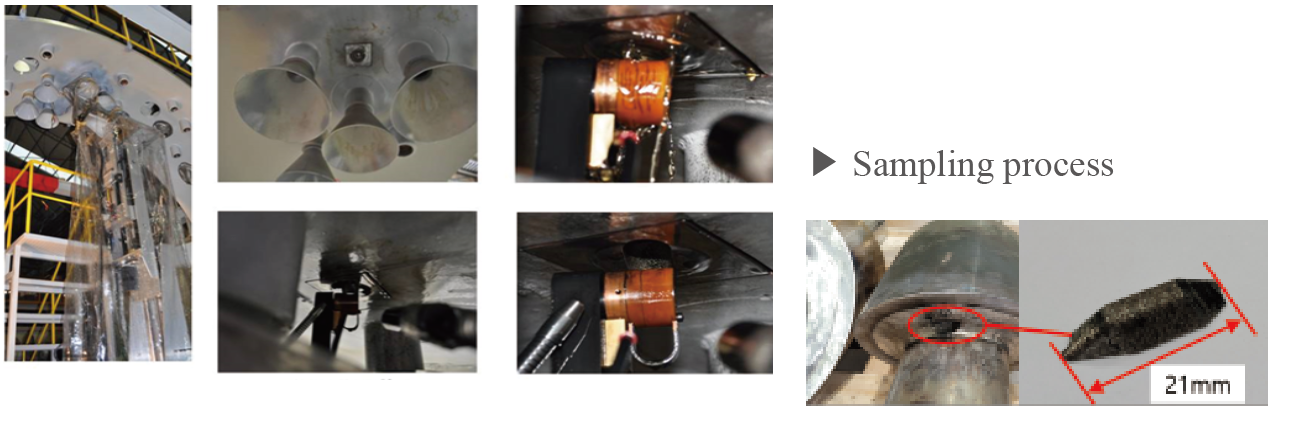

Boat sampling that can be applied in a short period without damaging the base material

This technology involves collecting samples from welded joints as a precise means to identify the exact causes of defects in equipment located within nuclear power plants. It allows underwater operations without affecting neighboring equipment. All nozzles and even spaces with nozzle angles of less than 40 degrees, can be accommodated. It also has radiation resistance, making it suitable for work inside a nuclear power plant. Specifically, ensuring durability of at least twice the exposure time of the entire process, and has been deployed in actual field applications.

It is equipped with a manipulator for collecting samples, allowing remote sample collection as well. In this case, control programs that can be used include underwater EDM equipment motion control, EDM power control, camera position

control, and circulation device flow control, among others.

Risk Factor Control

• Power Loss Prevention UPS (Uninterruptible Power Supply) for Power Plants: To prevent electrode jamming and sticking, a backup power supply UPS is installed for the purpose of returning the electrode to its original position.

This is done by collecting statistical data on the Material Removal Rate (MRR) per unit length in a distributed water environment. If the processing rate indicates that the sampling can be completed using the UPS power, the boat sampling continues. Otherwise, the electrode is reliably returned to its original position.

• EDM Debris Management: It purifies EDM debris by suctioning it from the chamber's interior through the external processing fluid tube.

• Sample Retention: It prevents sample detachment from the chamber by applying a gripper connected to the suction nozzle.

'업무 > 공유업무' 카테고리의 다른 글

| EDM In-bore System (Thermal Tube Cutting ) (0) | 2023.10.04 |

|---|